了解非金属材料的氢渗透测试

专职专家

格林摩根格林·摩根是弹性体应用方面的专家, 热塑性塑料 and composite polymer materials within the 石油 and Gas sector.

As more countries join together and commit to decarbonization following a declaration of a climate emergency, 对清洁能源的需求从未像现在这么大. 需要实现清洁的潜力, 像氢这样的智能能源现在比以往任何时候都更加迫切. 如果各国要实现净零排放目标, it is widely acknowledged that 氢 is going to be required to play an essential role.

根据 氢委员会, 目前有30多个国家制定了氢能发展路线图, 宣布了228个跨价值链的大型氢能项目, 其中85%位于欧洲, 亚洲, 和澳大利亚. 如果所有的项目都取得成果, total investments will reach more than $300 billion in spending through 2030.

成功部署 氢, 然而, will be critically dependent on the appropriate infrastructure and materials (including 弹性体, 热塑性塑料, 和复合材料), 以及确保其安全性和寿命所需的保证和测试.

为什么要对溶液进行氢渗透测试?

因为氢分子小, 它可以渗透聚合物, 或非金属, materials much faster than methane or other 气体es traditionally associated with fossil fuels. This includes 复合材料 comprising a high proportion of glass or carbon fibers such as those used in pipelines. 这意味着确定哪些材料性能最好是至关重要的, 它们抵抗氢的能力如何, 以及它们可以使用多久.

氢 permeation testing can provide manufacturers with important knowledge such as how much 氢 is going to pass through the material if decompression cycles are going to compromise structural integrity, and if the material will be able to stay in service for an agreed period of time.

长期以来,测试一直是该计划的关键部分 石油和天然气 工业安全流程, measuring permeability characteristics of deep well components such as seals, 压力屏障和衬垫. 随着氢经济的发展, 越来越多的im体育平台app下载超越了石油和天然气, 氢的产生和传输, 也在关注氢吗, 使测试在航空航天等其他im体育平台app下载更加普遍, 运输, 以及重工业的燃油系统部件等, 储氢罐, 化学加工基础设施.

什么是氢气渗透测试?

氢 permeation testing involves analyzing three key aspects of a material’s performance. 首先, a high-pressure 气体 permeation test can measure how quickly 氢 passes through materials in comparison, 例如, 甲烷, 压力高达150巴,温度从零下到200摄氏度. im体育APP, 例如, currently conducts tests with 氢 on 弹性体 and 热塑性塑料 at pressures of 150 bar with plans to increase this capability to 600 bar and has been able to compare permeation rates to previously tested 气体es.

The diagram below shows 氢 versus methane permeation through a thermoplastic at 40C and 40 bar, 氢气的渗透速度大约是甲烷的40倍.

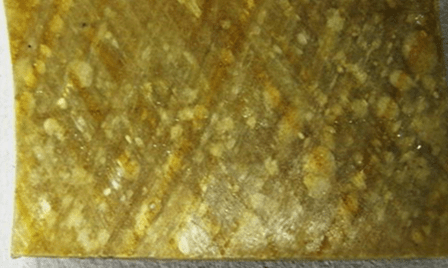

Secondly, as part of the permeation process, 气体 becomes dissolved in the material. 当施加的压力被移除时, this 气体 tries to escape from the material and can cause damage in the process, 称为快速气体减压(RGD)损伤. Some 气体es cause significant problems to non-metallic materials including 复合材料. The potential for 氢 to cause damage needs to be investigated due to the risk of it affecting component integrity, 如下图GRE管壁所示. 该测试可在150bar和150C的压力下进行.

第三个方面是老龄化, examining how non-metallic materials behave long-term when exposed to 氢. This is addressed by measuring changes in mechanical performance over time when the material is saturated with 氢. 在复合材料, it is the interface between the fibers and the resin matrix where degradation mechanisms might become evident. This testing can be undertaken at 150 bar and 150C for many months to replicate or accelerate in-service conditions.

A long-term aging test can also be combined with a decompression test to see if aging degradation results in a reduction in decompression resistance.

非金属材料的im体育APP试验按哪些标准进行?

im体育APP commonly tests to a variety of industry-recognized standards, including:

- 渗透性ASTM D1434, ISO 2782-1

- RGD iso 23936

- 老化ISO 23936

- NORSOK m - 710

- 此外,还有许多NACE和api相关的标准

除了, im体育APP can work with you to design and implement customized permeation test programs, which we frequently provide to clients for components such as O-rings and sealing elements. 如果需要,我们也可以集成几个 聚合物测试 方法集成到单个测试程序中.

准备进行氢气渗透测试时的关键考虑因素?

准备测试时, it is important that the manufacturer is clear about what they would like to achieve from the process, whether this is identifying the permeation rate or understanding and modifying the material or component to reduce permeation. 样品也需要适当的考虑,以确保程序的成功.

Questions that might need to be given advance consideration include the length of term the component or material will be in use, 如果在操作过程中减压可能是一个问题,

if the component will be in an enclosed environment where accumulation of permeated H2 could potentially become hazardous, 以及一条输送立方米氢气的长管道是否经济可行. Our 氢 experts work closely with the manufacturer in preparing to test, helping to ensure the right questions have been asked to ensure a smooth test process.

im体育APP has 30 years experience of in testing materials in high-pressure 气体 environments and is now sharing its expertise developed in the 石油和天然气 industry with other industries looking towards utilizing 氢. 的成员 亨利·罗伊斯研究所 委员会, 英国国家先进材料研究与创新研究所, im体育APP has also participated in the writing of the ISO 23936 series of Standards.

With very few test houses that are able to demonstrate proven expertise and capability in this sector, our experts have built up a wealth of experience in permeation and decompression damage mechanisms including visual observation of the phenomenon at high pressure for a variety of materials and components.

有关氢气渗透测试的更多信息,请 im体育APP 今天.

找到相关的 资源

相关服务

复合材料测试

im体育APP’s composite raw material testing helps manufacturers understand the physical, 热, and mechanical properties of the constituents used to create their composite product.

复合材料疲劳试验

无论是测试一个特定的标准还是开发一个定制的程序, im体育APP’s experts are ready to assist with your composite fatigue testing needs.

复合材料损伤容限试验

im体育APP offers a variety of test methods that provide manufacturers with more insight into their composite materials’ damage tolerance and resistance.

涂料测试

我们提供世界一流的聚合物材料专业知识, 弹性体, 热塑性塑料, 复合材料, 结构粘合剂. 在英国拥有全球范围的涂料实验室, 美国, 欧洲, 和亚洲, im体育APP provides a comprehensive range of coatings testing services to the 能源, 航空航天, 国防, 及运输界别.